Toolmaster® Tooling materials

| Name | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Name TB-BMI-G48 | DescriptionHigh temperature bismaleimide tooling boards | ||||||||

| Name | |||||||||

| Name BMIGP Carbon Prepreg | Description- | ||||||||

| Name | |||||||||

| Name Aquablock | DescriptionHigh temperature water soluble tooling block | ||||||||

| Name | |||||||||

| Name CEP Carbon Prepregs | DescriptionCyanate / epoxy tooling prepreg | ||||||||

| Name | |||||||||

| Name LTC Fiberglass & Carbon Prepregs | DescriptionLow temperature curing epoxy tooling prepregs | ||||||||

| Name | |||||||||

| Name TMFP Fiberglass & TMGP Carbon Prepregs | DescriptionEpoxy tooling prepregs | ||||||||

| Name | |||||||||

| Name Beta Prepreg | DescriptionHigh stability room temperature storage tooling system | ||||||||

| Name | |||||||||

| Name Beta TX670 DISCO Prepreg | DescriptionHigh stability room temperature storage tooling system | ||||||||

| Name | |||||||||

| Name OOA Beta Prepreg | DescriptionHigh performance tooling prepreg system | ||||||||

| Name | |||||||||

| Name TMR 2001A / TMH 2001B | DescriptionHigh temperature laminating resin for room temperature cure | ||||||||

| Name | |||||||||

| Name TMSF 5001A / TMH 5001B | DescriptionSurface fill | ||||||||

| Name | |||||||||

| Name TMSF 5005A / TMH 5005B | DescriptionHard surface fill | ||||||||

| Name | |||||||||

| Name Airfill 2 | DescriptionHigh temperature quick setting filler paste | ||||||||

| Name | |||||||||

| Name Carbon, carbon triaxial & fibreglass fabrics | DescriptionFabrics for resin infusion and standard laminate tooling | ||||||||

| Name | |||||||||

| Name TMSFR 5100A / TMSFHR 5100B | DescriptionSurface coat with reflow for our prepreg tooling systems | ||||||||

| Name | |||||||||

| Name Masterflex ''S'' Series | DescriptionFlexible spiral square tube | ||||||||

| Name | |||||||||

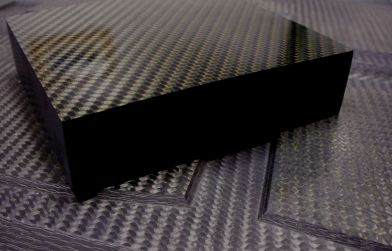

| Name TB-G48 & TB-F48 | DescriptionHigh temperature carbon/epoxy & fibreglass/epoxy tooling boards | ||||||||

| Name | |||||||||

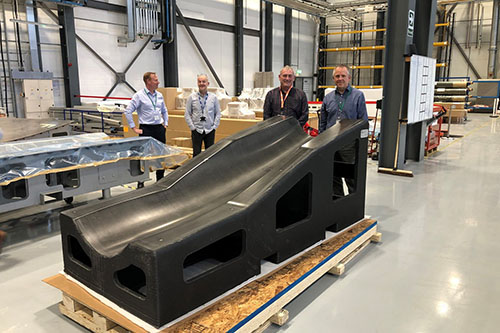

With our unique capabilities, we can not only provide a wide range of tooling materials for direct purchase; we can also assist you with the initial concept and prototype design, or even provide additional capacity by manufacturing or casting production tooling or parts to meet your specific needs.

Airtech is a prominent provider and manufacturer of tooling for prepreg processing, vacuum infusion, glass lamination, and other industrial applications. Our customers come from a wide range of industries, including Aerospace, Wind Energy, High-Performance Automotive, Motorsport, Marine, Solar Energy, and many more.

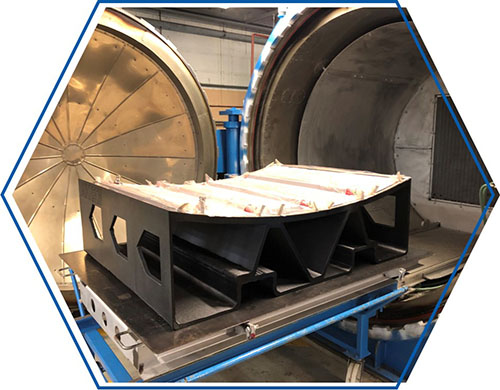

Toolmaster® tooling materials include an assortment of prepregs, surface coats, repair fillers, lamination resins, and tooling boards for back up structure fabrication. These tooling solutions include everything from low temperature initial cure systems, to high glass transition temperature (Tg) systems for use up to 500°F (260°C). Airtech's LTC Fiberglass and Carbon Prepregs offer a low temperature initial cure and high temperature use after post cure.

One benefit of the low initial cure temperature is the reduction of thermal expansion of the master model, improving mold accuracy.Airtech also offers Beta Prepreg, its Benzoxazine resin system, on a variety of reinforcements. These include 2x2 twill as well as triaxial, quasi-isotropic systems to reduce layup times and complexity in the fabrication of composite tooling.Beta Prepreg is also available as Beta TX670 DISCO, which are pre-cut sheets with discontinuous fibers for maximum drapability in layup.

For maximum high temperature performance, Airtech’s CEP prepreg systems are the obvious choice.

About

Featured Posts

Contact info

Address: 5700 Skylab Road,

Huntington Beach, CA 92647

United StatesPhone: +1 714 899 8100