Print-Tech®

Airtech expertise has added value to Large Scale Additive Manufacturing and taken it to the next level. Airtech is utilizing its facilities in Springfield, TN (USA) and Differdange, Luxembourg to house a pair of 40ft x 10ft (12m x 3m) large scale additive manufacturing machines to offer its Print-Tech® full-service tool manufacturing solution. Exclusively with Dahltram® resins, in-house researched and developed specifically for advanced composite tooling applications.

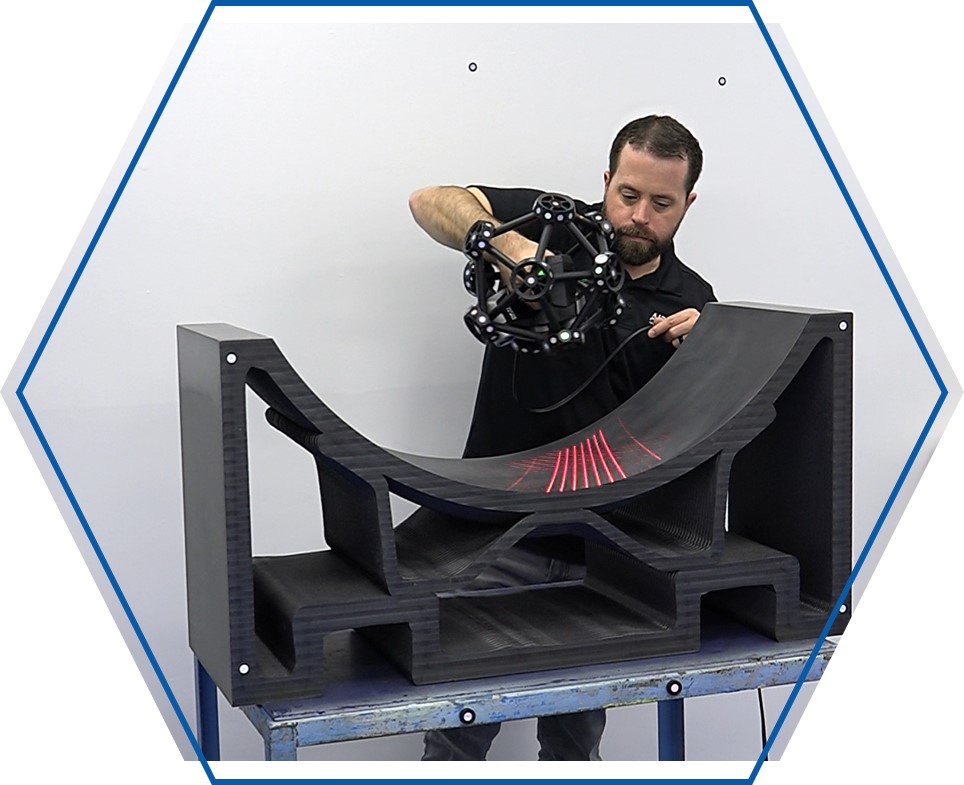

- Innovation - Patent process innovations and trademark products for unique high temperature and room temperature applications.

- Lead Time - Rapid tooling from design to the production floor in significantly less time than conventional methods.

- Cost - Substantial reduction in touch labor and material waste for significant savings.

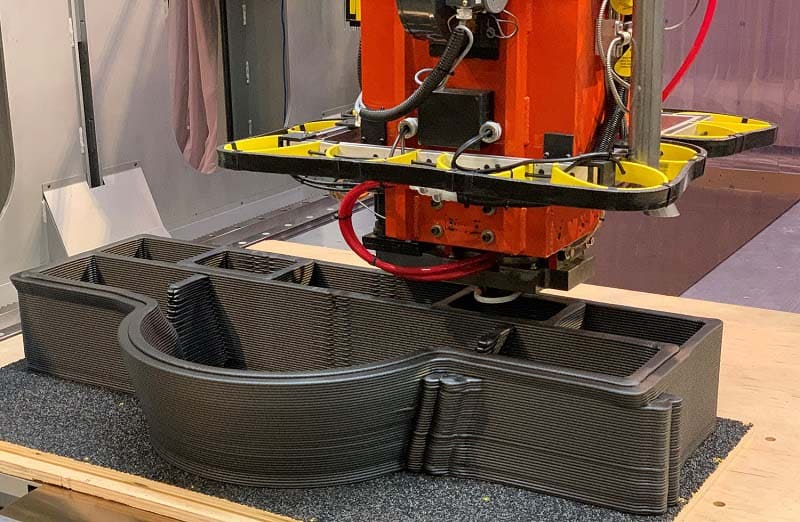

- Scale - Diverse solutions with large scale 3D printing capability.

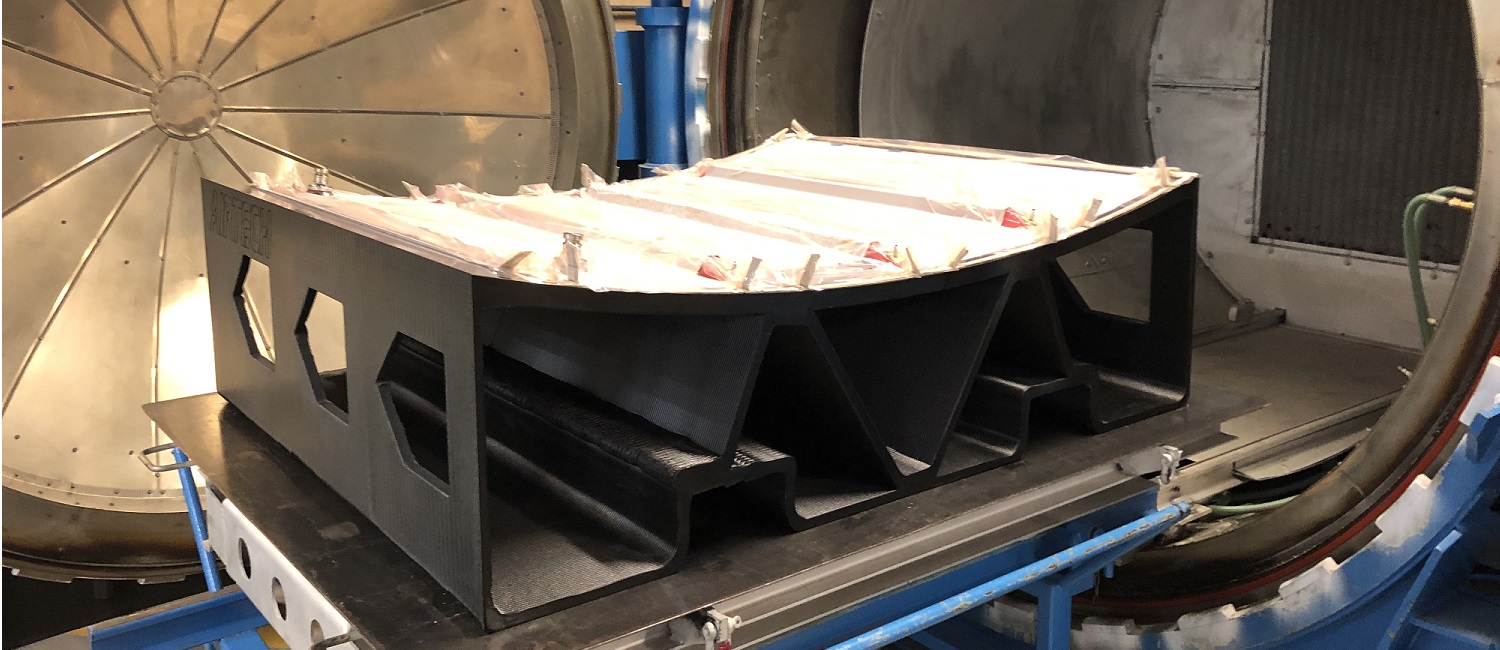

With over 50 years of extrusion and compounding experience, Airtech is bringing its expertise to Large Format Additive Manufacturing (LFAM) and taking it to the next level. With its facilities in Springfield, TN, USA, and Differdange, Luxembourg, being utilized to house some of the largest available 3D printers. These additive machines measure in at 40ft x 10ft (12m x 3m) to offer Airtech's Print-Tech®, a full-service manufacturing solution. For exclusive use in Print-Tech® services, Airtech has developed a new series of innovative polymer composite resins, Dahltram®, for use in large-scale 3D printing. With the Dahltram® additive resin series, Airtech has addressed the need for lower CTE (Coefficient of Thermal Expansion) and a more robust service life when used at low or high temperatures, including use in an autoclave or metal forming applications. Dahltram® polymer composite resins are designed for use in any pellet-fed FDM printing system.

Print-Tech® applications include, but are not limited to: molds for autoclaves and ovens, infusion tooling, jig and fixture tooling, custom tooling, rapid prototypes, and functional applications. With significantly less lead time than conventional methods, a substantial reduction in touch labor, and a reduction in material waste for significant savings, Airtech's Print-Tech® is an easy choice.The Print-Tech section of our catalog also includes a wide variety of products for all uses and applications relating to additive manufacturing.

About

Featured Posts

Contact info

Address: 5700 Skylab Road,

Huntington Beach, CA 92647

United StatesPhone: +1 714 899 8100