Release Films

| Name | Description | Maximum use temperature | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Name Wrightlon® 3700 | DescriptionLow cost release film for commercial and wind energy applications | Maximum use temperature121°C (250°F) | |||||||

| Name | |||||||||

| Name Wrightlon® 3800 | DescriptionLow temperature PET release film | Maximum use temperature93°C (200°F) | |||||||

| Name | |||||||||

| Name Wrightlon® 3900 | DescriptionInexpensive polyolefin release film | Maximum use temperature157°C (315°F) | |||||||

| Name | |||||||||

| Name Wrightlon® 4500 | DescriptionHalohydrocarbon polymer release film | Maximum use temperature204°C ( 400°F) | |||||||

| Name | |||||||||

| Name Tedlar® by DUPONT™ | DescriptionStrong, flexible and resistant PVF films | Maximum use temperature | |||||||

| Name | |||||||||

| Name Wrightlon® 4600 | DescriptionCost effective polyolefin copolymer release film | Maximum use temperature193°C (380°F) | |||||||

| Name | |||||||||

| Name A4000 | DescriptionHigh performance fluoropolymer release film | Maximum use temperature260°C (500°F) | |||||||

| Name | |||||||||

| Name A4000 LFST | DescriptionHeat shrinkable release film tube | Maximum use temperature260°C (500°F) | |||||||

| Name | |||||||||

| Name Wrightlon® 5200 | DescriptionHigh performance fluoropolymer release film | Maximum use temperature260°C (500°F) | |||||||

| Name | |||||||||

| Name Airtech MR1/MR2 | DescriptionUltra high temperature release films | Maximum use temperature315°C (600°F) | |||||||

| Name | |||||||||

| Name Thermalimide RCBS | DescriptionUltra high temperature release film | Maximum use temperature405°C (761°F) | |||||||

| Name | |||||||||

| Name Dahlar® Release Bag 125 | DescriptionEconomical release film | Maximum use temperature140°C (285°F) | |||||||

| Name | |||||||||

| Name Available Perforations | Description- | Maximum use temperature- | |||||||

| Name | |||||||||

| Name Resin Compatibility | DescriptionRelease film selection guide | Maximum use temperature- | |||||||

| Name | |||||||||

| Name Commonly Used Sizes | DescriptionRelease Films | Maximum use temperature- | |||||||

| Name | |||||||||

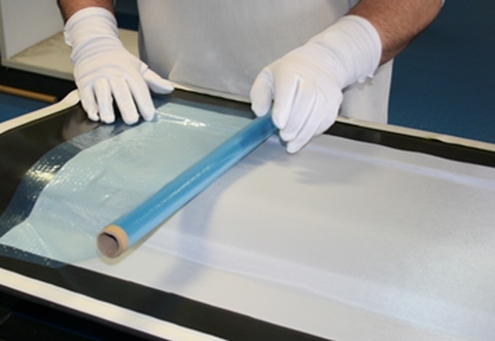

Films for release processes are specially designed to meet a variety of applications within composite manufacturing processes.

By using Airtech release films, other process materials, such as breather fabric and flow media, can be removed from composite parts. A qualified team of technicians delivers high-quality services that are easy to access, easy to personalize, and easy to customize.

Release Films are used in the composite manufacturing process not only to ensure release from breatherand other vacuum bagging products, but also to control the flow of resin.Solid release films are used to completely contain the flow of resin within the laminate, whereas perforated release films offer a controlled bleed of excess resin into the bleeder cloth.

The use of release film will vary based on application, but Airtech as the manufacturer, has engineered a release film that is effective and economical for every application. Airtech offers the widest selection offluoropolymer release filmson the market with A4000 and WL5200 offered from stock up to 120inch(3.05m) wide.

Release Films are available for use at all temperature ranges up to 752°F (400°C).Airtech release films are manufactured in both non-perforated and perforated styles. Review the ‘Available Perforations’ page in Release Films section of the catalog for perforation details.

About

Featured Posts

Contact info

Address: 5700 Skylab Road,

Huntington Beach, CA 92647

United StatesPhone: +1 714 899 8100