Description

Benefits

• Low initial cure temperature for low thermal expansion effect during curing and ability to use low cost master model materials.

• Nano technology delivers outstanding toughness & high Tg. (218ºC) for long tool life and reduced life cycle cost.

• Low viscosity allows infusion of thicker and more complex laminates with fewer resin feed lines.

• In comparison to metallic tools, Toolfusion® 3A/ 3B composite tools are lighter weight for easier manual handing.

• In comparison to metallic tooling, Toolfusion® 3A/ 3B composite tools have faster heat up and cool down rates for reduced production costs.

• Toolfusion® 3A/ 3B composite tooling laminates have vacuum integrity for vacuum bag processing of parts in oven and autoclave.

Technical data

| Test method | ||

| Material type | Epoxy | |

| Colour | Black : Clear (A : B) | |

| Mix ratio by weight | 100 : 85 (A : B) | |

| Pot life | 300 minutes (100 g at 22°C) | |

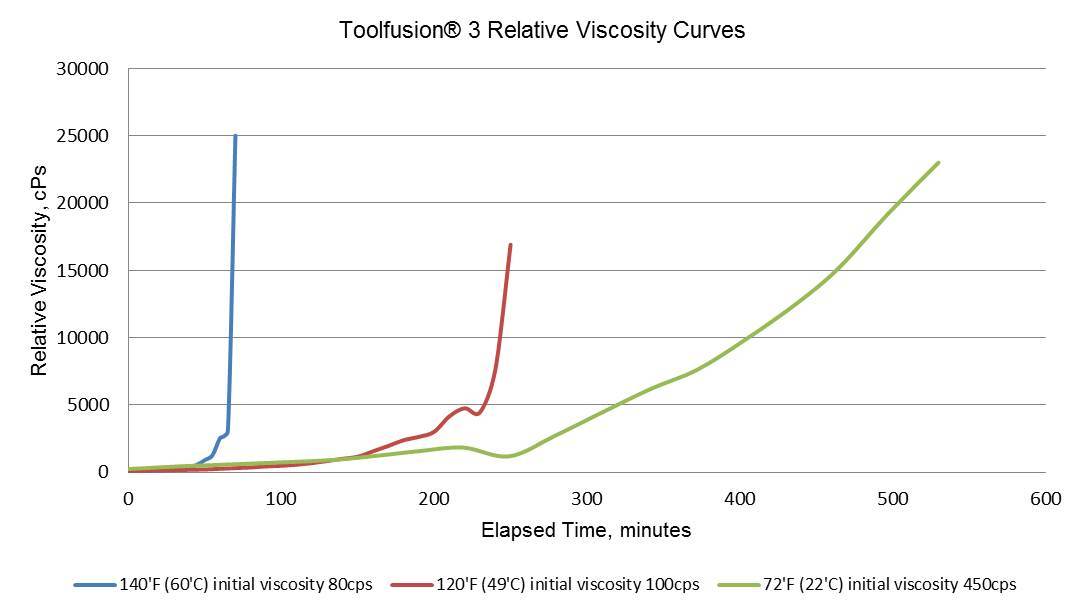

| Viscosity (initial at 22°C) | 450 cps | |

| Density (mixed) | 1,13 g/cm3 | |

| Glass transition temperature | 218°C (425°F) | |

| Hardness | 89 Barcol | ASTM D2583 |

| Shrinkage | 0,9 % | |

| Shelf life | 12 months from date of shipment when stored in original packaging at 22°C |

Sizes

| Packaging Part A | Packaging Part B | Weight Part A | Weight Part B |

|---|---|---|---|

| 5 gallons | 5 gallons | 20.4 kg (45 lbs) | 18.1 kg (40 lbs) |

Curing data

• Cure laminate on master model with full vacuum applied.

• Raise temperature to 49ºC (120ºF) and hold for 12 hours.

• Remove vacuum bagging materials and attach back-up structure if required.

• Carefully remove the laminate continue with post cure.

Post cure schedule:

• Ramp to 65ºC (150ºF) and hold for 60 minutes.

• Ramp to 93ºC (200ºF) and hold for 60 minutes.

• Ramp to 121ºC (250ºF) and hold for 60 minutes.

• Ramp to 149ºC (300ºF) and hold for 60 minutes.

• Ramp to 177ºC (350ºF) and hold for 60 minutes.

• Ramp to 204ºC (400ºF) and hold for 120 minutes.

Sustainability

Notes

Last updated : 2026-02-08

As the conditions or methods of use, including storage, are beyond our control, Airtech International, Inc. does not assume responsibility for the performance of this material for any particular use. The material is sold "as is". Airtech International, Inc. disclaims, and buyer waives, any and all implied warranties, including without limitation the implied warranties of merchantability and of fitness for particular use. The information contained herein represents typical properties and should not be used for specification purposes. Any translation is provided for your convenience only. The official language is English and the official law is California, USA.

Enter your email to view the product detail

About

Featured Posts

Contact info

Address: 5700 Skylab Road,

Huntington Beach, CA 92647

United StatesPhone: +1 714 899 8100